According to the American Society of Civil Engineers’ report card on America’s infrastructure, leaking pipes lose an estimated six billion gallons of clean drinking water per day, and 240,000 water main breaks occur each year. With demand for clean drinking water continuing to increase as the population grows, and as we see the detrimental impact that broken pipes can have on cities and towns, the prevalence of pipe leaks needs to be addressed.

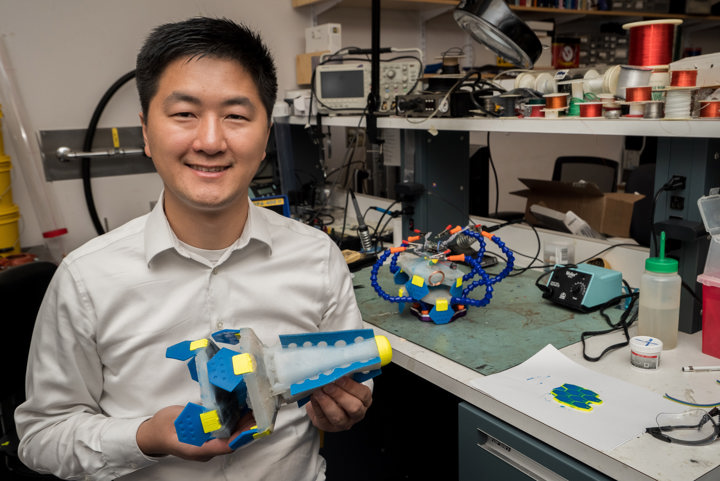

You Wu, PhD, a recent doctoral graduate of the Massachusetts Institute of Technology set out to solve this problem. His solution, Lighthouse, is a low-cost robot that travels through water pipes to proactively find leaks before they become a problem, and the winner of the 2018 James Dyson Award.

Lighthouse is built from soft, flexible material and uses a special tactile sensor to detect leaks in underground water pipes. To use Lighthouse, a technician simply inserts the robot into a water pipe through an existing hydrant. As the robot passively flows through a pipe and navigates around pipe elbows, the sensor is tugged by the suction force of a water leak. When a leak is detected, Lighthouse measures the strength of the tug and records the location of the leak. Once the robot is flushed out of the pipes through a hydrant, the technician can wirelessly download a map of leaks from Lighthouse.

Existing methods of leak detection, such as geophones and acoustic correlators, are inherently flawed, as they search for the sound of leaks. These acoustic devices often find leaks that are already losing at least ten gallons of water per minute, which is twice the flow rate of a typical shower. In other words, these devices catch leaks too late. With its unique tactile sensor, Lighthouse can find leaks when they are losing only one gallon of water per minute, identifying leaks before they become catastrophic.

Designer Dr. Wu says:

“My interest in environmental sustainability started in childhood with a conflict between resource scarcity and population growth. When I grew up in China, my community had one day without power and another day without water every single week. The city regulated the supply to all communities to lower the burden on the power grid and water system. I grew up thinking we were good citizens conserving energy and water for the greater good. However, when I learned that every day 20 percent of clean water in the world is lost due to leaks while we were making a sacrifice to conserve water, I thought this was wrong and I needed to change it.”

Judge Isis Shiffer, Founder of Spitfire Industries and 2016 international winner of the James Dyson Award, says:

“What attracted me to this design is that even though it’s using cutting-edge technology, it’s still a very straightforward and simple solution. It is finding a physical problem in a physical way, and it’s also very practical. Everyone’s encountered torn-up streets due to water leaks, and if that can be prevented, it could help with quality of life in cities and even rural areas that might not get as much attention. This is a really elegant and light-weight solution.”

The Runners-up

The two runners-up in the US competition of the James Dyson Award are joining Lighthouse in progressing to the international round of the competition, which features 20 projects.

Infinite Cooling– Designed by Massachusetts Institute of Technology student Maher Damak

Infinite Cooling is a technology that reduces operational costs for power plants and alleviates water stress for nearby communities by recovering large quantities of clean water from cooling tower plumes. Vaporized water droplets from the power plant are zapped with a beam of ions and are collected on wire mesh. The droplets then fall into a temporary reservoir and can either be reused in the power plant or sent to a city’s water supply system. Infinite Cooling can be retrofitted onto any type of cooling tower or integrated into new cooling towers.

Night Loo– Designed by ArtCenter College of Design student Anna Meddaugh

Night Loo is a portable, personal urinal that allows women and girls living in refugee camps to safely go to the bathroom at night. The petal-like flaps act as a splash guard when open, and cover the contents of the urinal when closed. After relieving herself, the user empties a packet of pre-portioned dissolving PVA film, which turns liquid waste into an odorless powder in under a minute. The powder is then emptied through a spot that pops out of one end of the device. The urinal can also be unfolded to be flat, making it easy to clean.

Share this page on