What it does

UNBLOK prevents domestic fat, oil, and grease (FOG) blockages using a bio-composite filter system derived from palm oil industry waste, simplifying sewage treatment.

Your inspiration

In many Malaysian households, used cooking oil isn’t just poured down the sink; it also enters drains through daily dishwashing, as grease from plates and pans washes away. This daily habit causes FOG buildup in pipes, leading to clogs, odors, and long-term plumbing damage. Over time, it contributes to water pollution and strains sewage systems. Despite its impact, improper oil disposal is often overlooked, especially in homes with low-flow drainage, where blockages form faster and are harder to remove.

How it works

UNBLOK is a passive filtration system designed to intercept and trap FOG from kitchen wastewater, operating without electricity or chemicals. Its core component is a bio-composite sheet made from compressed palm oil fiber. This material leverages natural oleophilic properties, proven to effectively attract and retain oil and grease. Wastewater enters through an inlet pipe into a central tube. A closed bottom forces the water laterally through perforations in the tube’s walls, dispersing it into the surrounding palm fiber filter layer. As the wastewater permeates this layer, the fiber sheet absorbs and traps FOG and food residues via capillary action and surface adhesion, while allowing clarified water to flow onward. The filtered water then passes through an outer perforated mesh wall. This mesh provides structural support for the fiber layer while acting as a final barrier, permitting only treated water to exit through the outlet at the bottom.

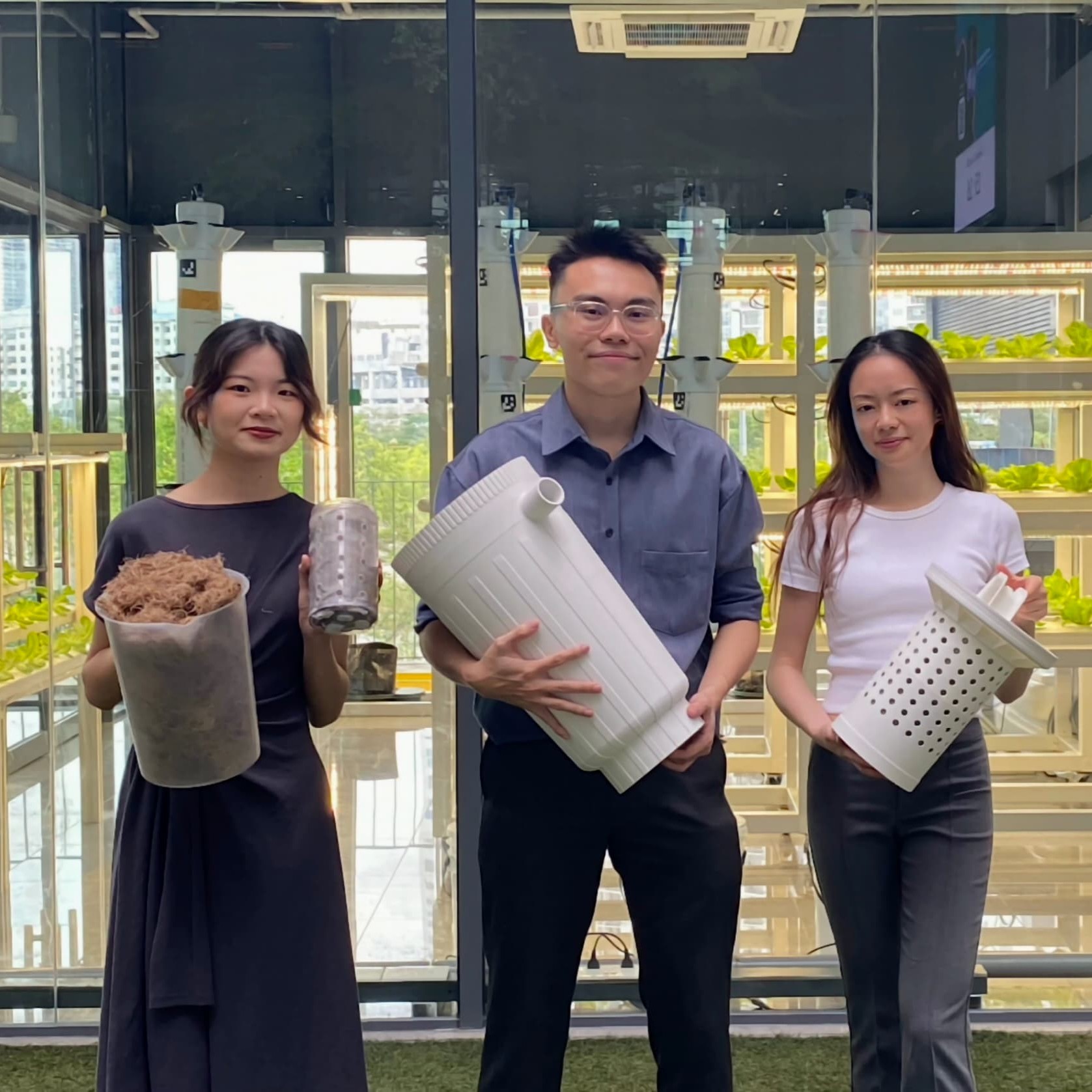

Design process

Our journey began with research into the environmental and household impacts of improper cooking oil disposal, especially its strain on sewage systems. The issue became personal when we experienced slow drainage, foul odors, and the frustration of repeatedly clearing clogged kitchen pipes. Seeking a solution, we explored agricultural waste and identified palm fiber, a palm oil industry byproduct, as a promising sustainable material. Early prototypes using simple bio-composite sheets proved impractical in real kitchens. Modifying standard sink parts improved design but not performance. Developing a dedicated filter system, we faced a key challenge: balancing water flow with oil absorption. Many materials either held too much water or blocked flow, reducing usability. Testing various natural fibers, durian husk, sugarcane bagasse, bamboo husk, palm fiber proved best for its oil retention, structure, and local availability. We also found that even small texture differences affected absorption and flow. A breakthrough came with the addition of wire mesh, which provided structure, distributed flow evenly, and prevented fiber collapse, turning loose fill into a stable, functional filter unit.

How it is different

Our FOG filtration system redefines domestic kitchen waste management by transforming palm oil industry byproducts into effective, fully biodegradable filters. Stepping out of conventional bulky, costly, and high-maintenance grease traps, our solution is compact, eco-friendly, and designed for everyday household use. It passively captures fat, oil, and grease (FOG) at the source using palm fiber’s natural oleophilic properties, preventing drain clogs and reducing environmental harm. Modular and easy to install, it integrates seamlessly into standard sinks. Crucially, the used filter is biodegradable and can be upcycled directly into agricultural fertilizer, completing a circular loop. This sets the foundation for a fully closed-loop, zero-waste system ready to be adapted by the industry, making responsible FOG disposal easily accessible and scalable.

Future plans

UNBLOK goes beyond households, enabling scalable community adoption where housing estates establish collection points for spent filters. These filters are transported to processing facilities, converting trapped FOG into fertilizer for palm plantations, thereby closing the resource loop. Critically, our bio-composite technology's moldability allows us to design interlocking floating barriers that actively absorb and remediate petroleum oil spills at sea, addressing a major environmental challenge. Furthermore, customized filter units can be deployed at sewage treatment plants and industrial drain points to intercept FOG on a large scale.

Share this page on