What it does

CRANKKUT is a portable ventilator that provides automatic respiratory support for individuals with stopped or weakened breathing. It was developed as an alternative to manual resuscitation bags, offering a mechanical solution inspired by automotive systems.

Your inspiration

As a first aider and designer, I analyzed the technical challenges of manual resuscitator bags. In these systems, a patient's life depends on the personnel’s manual skill. The correct air volume must be manually delivered according to the patient's age and weight. Moreover, the system usually requires two personnel, increasing the workload. According to PMID: 33138977, even professionals with over 10 years of experience can deliver incorrect volumes, risking lung injury. To solve this, I explored mechanisms that mimic the natural wave-like motion of breathing. Inspired by crankshaft and throttle systems, I developed CRANKKUT.

How it works

A 30 RPM geared DC motor drives the crankshaft mechanism, moving the piston to provide half a rotation for inhalation and half for exhalation per cycle. The piston completes the inhalation phase in about 1 second, matching the average adult’s breath duration. A Hall effect sensor detects the motor’s half rotation to control this timing. Respiratory rate is adjustable via 1-1, 1-2, 1-3 (inhale-exhale) modes. When the piston is up, a one-way valve allows only fresh air intake, blocking reserve air. When the piston moves down, a lower one-way valve releases compressed air from the electronics compartment to prevent overheating. Another mechanism, the rotary valve, provides different tidal volumes by pre-adjusting the air passage cross-section (maximum: 7 ml × 80 kg = 560 ml). The system operates using 3S 18650 batteries. Unlike manual bags, this device is set once by a single healthcare staff to suit the patient. All clinical values come from manual bag data.

Design process

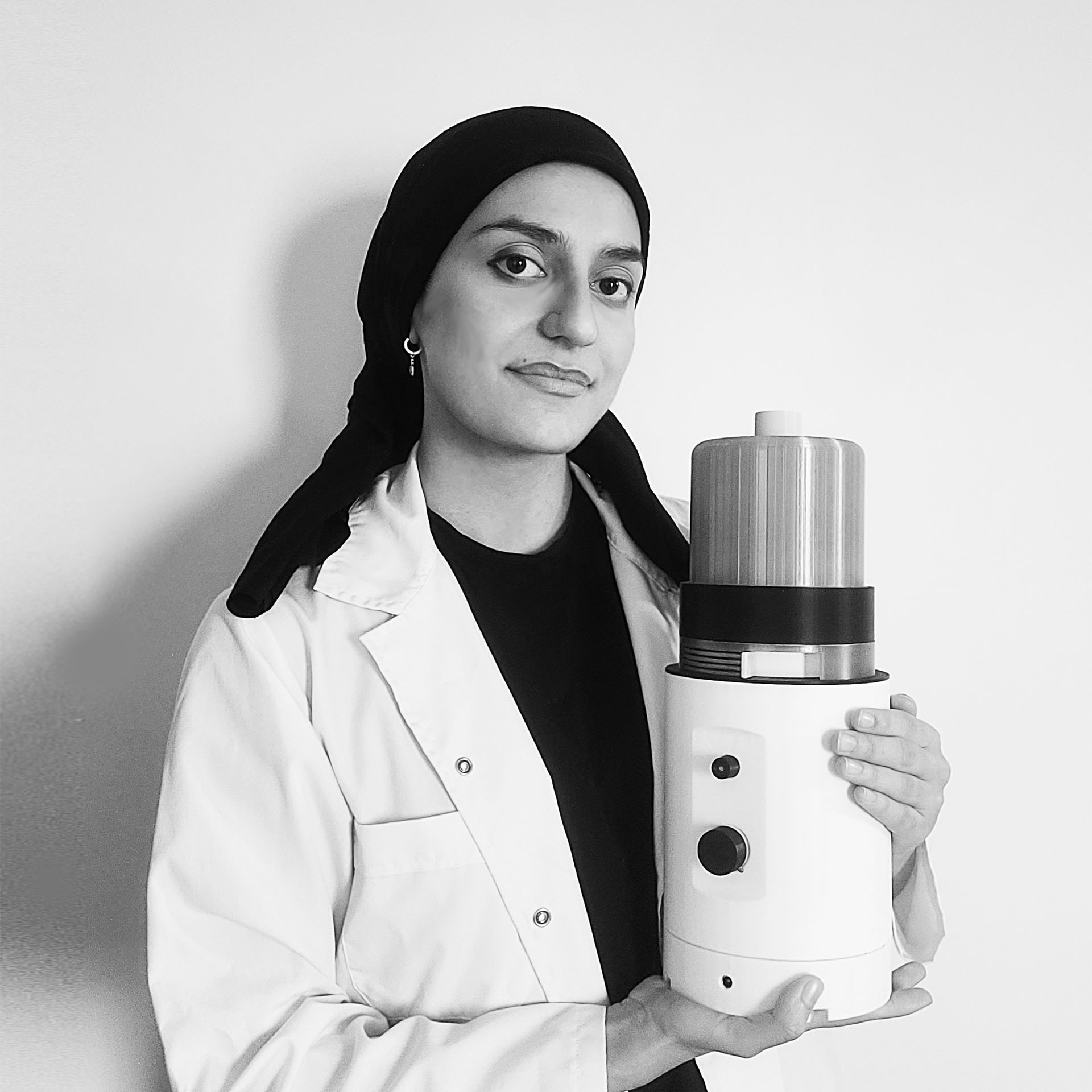

In critical respiratory situations, relying on a healthcare staff’s manual skills increases the risk of barotrauma and requires personnel to remain on duty for extended periods. I began researching wave-based systems that simulate natural breathing and require only a single adjustment. Inspired by the question “Can automotive mechanisms simplify ventilators?”, I explored crankshaft and throttle systems, sketching various spring-, magnet, and slider-based valves. I quickly moved to prototyping using 560 ml cylinders and tested air delivery through water displacement, aiming for 1 second breaths. Initial efficiency was 85%, and over 30 tests, I achieved 500–600 ml volumes. Before modeling, I analyzed minimalist products, as efficiency increased the device’s height and crank-based movement widened its diameter. After three redesigns, I achieved a form suitable for human ergonomics. The final version has a wider base to reduce tipping risk. Following Rams' design principles, I kept the product simple, clear, and user friendly. A transparent body allows users to observe piston movement in real time. After assembling the circuit and testing it, the final prototype was produced using a 3D printer. The total cost from electronics to final prototype was approximately $300.

How it is different

CRANKKUT offers a more compact and portable alternative to some startup projects that compress resuscitation bags with pistons. Commercial ventilators often rely on expensive linear actuators or stepper motors, which require constant directional changes, leading to wear on delicate lead screws. In contrast, CRANKKUT uses a simple DC motor running in a single direction to complete a full breathing period via a crankshaft. Its wave-like motion avoids sudden transitions at peak points, reducing the risk of barotrauma. Compared to other portable systems, it provides a low-cost, simplified, and standardized solution. As its name suggests, the integration of two automotive mechanisms (crankshaft and throttle) allows for a controlled and rhythmic imitation of human breathing. This unique approach sets CRANKKUT apart from other systems.

Future plans

This project can be positioned as an emergency ventilator alternative for disaster zones, ambulances, field hospitals, and resource limited areas. In the future, the device might allow patients to quickly share their respiratory status with healthcare professionals through a simple connection, potentially reducing unnecessary hospital visits. Furthermore, the system is planned to be further miniaturized and developed into a wearable device.

Awards

A patent application will be filed soon.

Connect